Application of Middle Voltage Radial Aluminum Electrolytic Capacitor and High Voltage Aluminum Electrolytic Capacitor in Frequency Converter

Frequency converters, also known as variable frequency drives (VFDs), are essential devices used widely in industrial automation, HVAC systems, renewable energy, and various other fields. They regulate the speed and torque of electric motors by controlling the frequency and voltage supplied to the motor. Key components that ensure the efficient and stable operation of frequency converters are aluminum electrolytic capacitors, specifically middle voltage radial aluminum electrolytic capacitors and high voltage aluminum electrolytic capacitors. Nantong Xingchen Electronics Co., Ltd., a renowned high-tech enterprise specializing in the research, production, and sales of aluminum electrolytic capacitors, provides advanced capacitor solutions that play a vital role in the performance of frequency converters.

Company Overview

Established in 1985, Nantong Xingchen Electronics Co., Ltd. has developed into a leader in the aluminum electrolytic capacitor industry. With state-of-the-art automated production equipment and robust independent research and development capabilities, the company produces approximately 1.6 billion capacitors annually. Their diverse product portfolio includes 240 million high-voltage patch series capacitors, 100 million polymer solid-state capacitors, 100 million horn series capacitors, and 2.5 million screw series capacitors. These products are widely applied in sectors such as new energy equipment, servo drives, switching power supplies, welding machines, charging stations, communication power supplies, solar and wind inverters, variable frequency household appliances, fast charging power supplies, and LED energy-saving lamps.

Role of Aluminum Electrolytic Capacitors in Frequency Converters

Frequency converters consist of several critical stages, including rectification, DC link energy storage, inversion, and motor control. Aluminum electrolytic capacitors primarily serve in the DC link stage, where they store and smooth electrical energy, filter voltage ripple, and ensure a stable DC voltage output for the inverter section.

The choice between middle voltage radial aluminum electrolytic capacitors and high voltage aluminum electrolytic capacitors depends on the specific voltage and current requirements of the frequency converter system.

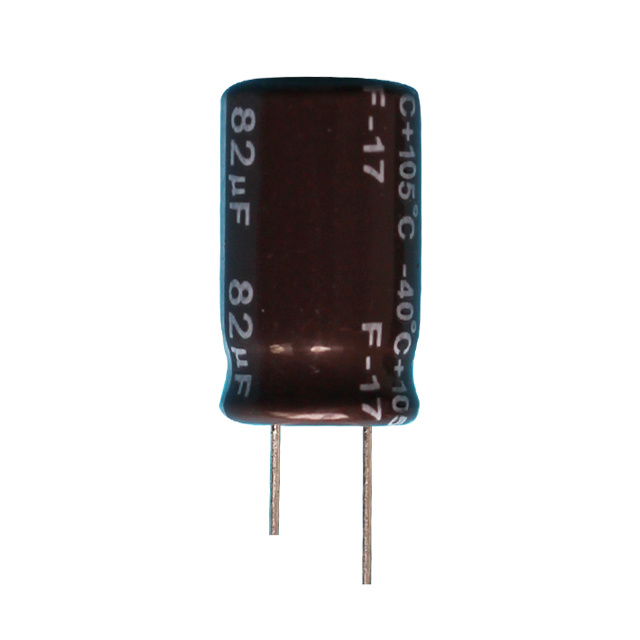

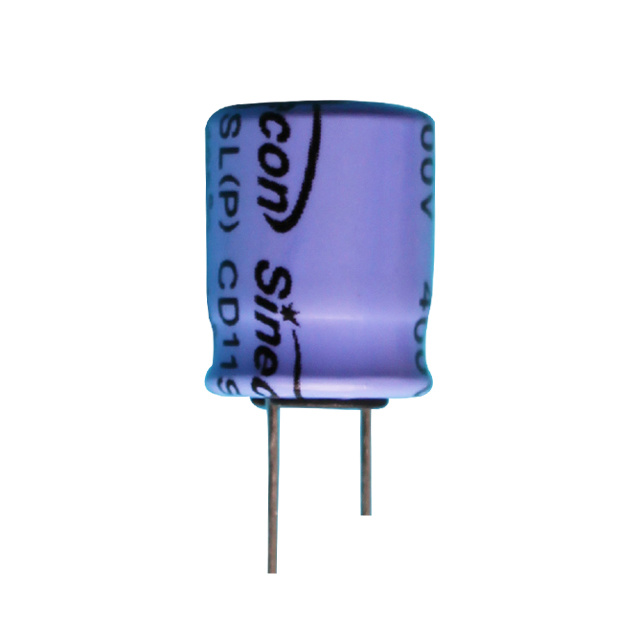

Middle Voltage Radial Aluminum Electrolytic Capacitors in Frequency Converters

Middle voltage radial aluminum electrolytic capacitors typically operate in voltage ranges from approximately 100V to 450V and are characterized by their radial lead structure. Their design allows compact installation and efficient heat dissipation, which are critical in the constrained environments of frequency converter power modules.

Key Features and Benefits

High Capacitance Density: These capacitors offer large capacitance values per unit volume, enabling sufficient energy storage in limited space.

Low Equivalent Series Resistance (ESR): Low ESR minimizes internal heat generation, enhancing the overall efficiency and reliability of the frequency converter.

Thermal Stability: Good tolerance to operating temperature fluctuations ensures stable performance under various environmental conditions.

High Ripple Current Capability: Middle voltage capacitors can handle significant ripple currents, common in frequency converter DC link circuits, without performance degradation.

Application Insights

In frequency converters, middle voltage radial aluminum electrolytic capacitors act as energy buffers that absorb voltage spikes generated by the inverter's switching transistors. By stabilizing the DC bus voltage, they help maintain smooth motor operation and reduce electromagnetic interference (EMI). Nantong Xingchen’s middle voltage capacitor product lines provide durable solutions tailored to meet the rigorous demands of industrial and commercial frequency converters.

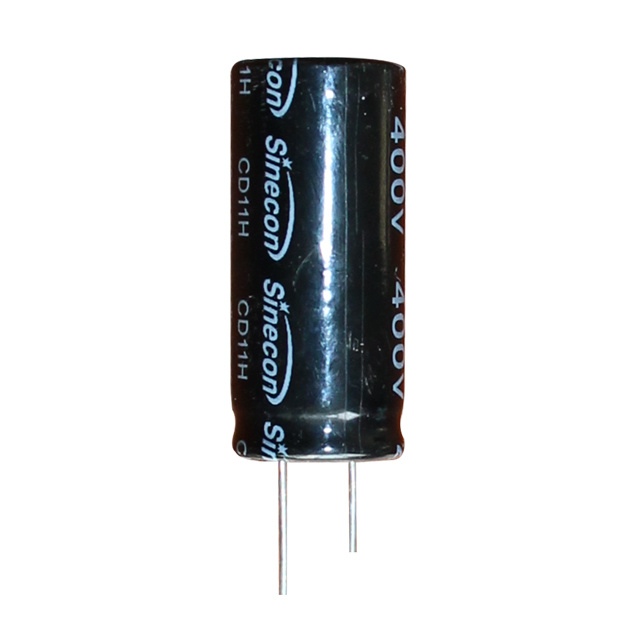

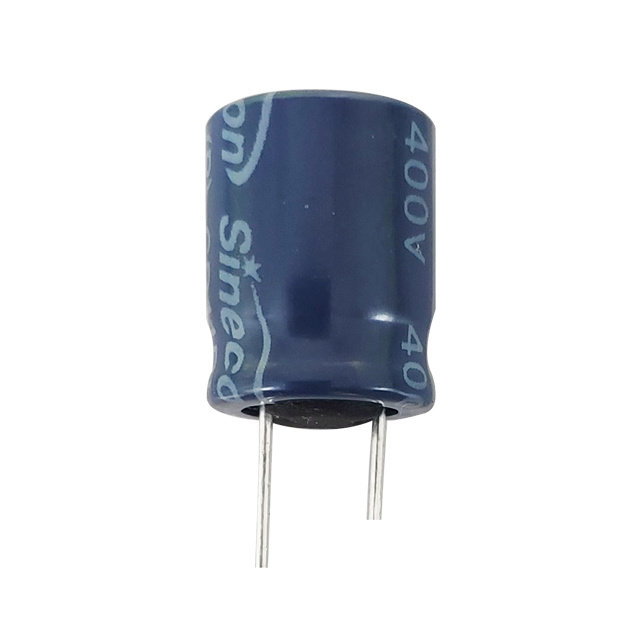

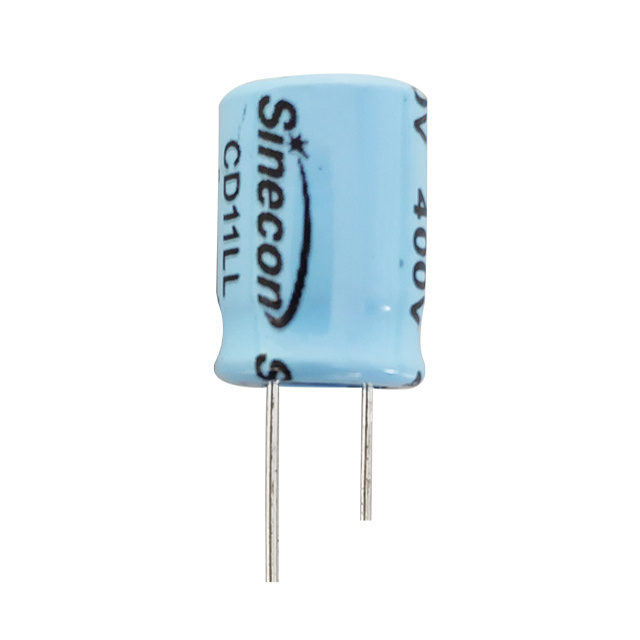

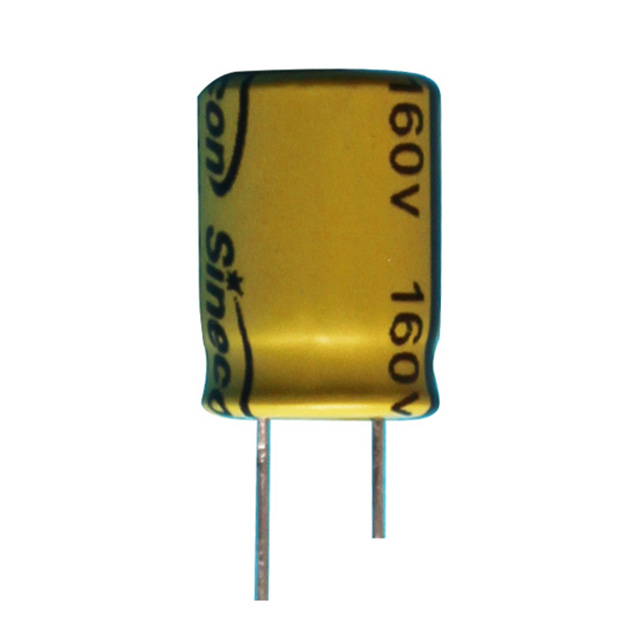

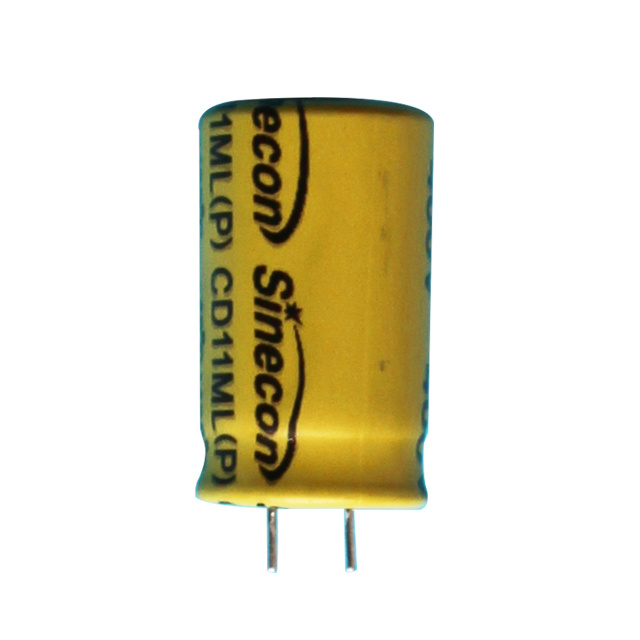

High Voltage Aluminum Electrolytic Capacitors in Frequency Converters

High voltage aluminum electrolytic capacitors are designed for voltage ratings typically above 450V, accommodating the requirements of high-power frequency converters and inverters. These capacitors are engineered to withstand high voltage stresses and transient surges often experienced in large-scale industrial applications.

Key Features and Benefits

Superior Voltage Withstanding Ability: High voltage capacitors feature enhanced dielectric layers and robust internal construction to tolerate elevated voltages.

Improved Reliability: Reinforced sealing and materials prevent electrolyte leakage and ensure longer lifespan under heavy-duty cycling.

Enhanced Surge Current Handling: Designed to manage large inrush and surge currents without premature failure.

Wide Operating Temperature Range: Capable of maintaining performance even in harsh environmental conditions.

Application Insights

In frequency converters used for heavy machinery or renewable energy applications, high voltage aluminum electrolytic capacitors provide the necessary voltage stability and energy storage to accommodate high power levels. Their role is critical in ensuring system safety and operational longevity. Nantong Xingchen’s high voltage patch series capacitors excel in these applications, delivering reliable performance and helping manufacturers meet stringent industrial standards.

Advantages of Nantong Xingchen Capacitors in Frequency Converter Applications

Nantong Xingchen Electronics leverages advanced manufacturing processes and precise quality control to produce capacitors that excel in both middle and high voltage categories. Some notable advantages include:

Large-Scale Production Capacity: The ability to supply massive quantities ensures availability for global industrial demands.

Product Diversity: Offering a comprehensive range of capacitors suitable for different voltage classes and applications.

Independent R&D: Continuous innovation in materials and capacitor design to improve performance and extend service life.

Stringent Testing: Full suite of testing and detection equipment guarantees capacitor quality, reliability, and safety.

Customized Solutions: Capability to tailor capacitor designs for specific frequency converter requirements.

The performance and reliability of frequency converters heavily depend on the quality of aluminum electrolytic capacitors used in their design. Middle voltage radial aluminum electrolytic capacitors and high voltage aluminum electrolytic capacitors are indispensable for energy storage, voltage stabilization, and ripple filtering within these systems.

Nantong Xingchen Electronics Co., Ltd., with its extensive expertise and advanced production capabilities, provides high-quality capacitors that meet the demanding specifications of frequency converters. Their capacitors ensure efficient operation, enhance system longevity, and support the advancement of industries relying on variable frequency drive technology.

As frequency converters continue to evolve with greater efficiency and smarter control capabilities, the role of reliable, high-performance aluminum electrolytic capacitors from companies like Nantong Xingchen will remain vital in supporting these technological advancements.