Robust Construction and Materials

The VH Small-Sized Aluminum Electrolytic Capacitor is designed with a robust construction that utilizes high-quality materials to withstand the stresses caused by inrush currents or surge conditions. The key structural element, the anode foil, is made from high-purity aluminum, which provides excellent conductivity while minimizing the risk of mechanical damage. The electrolyte—which is a key part of the capacitor's functioning—ensures electrical stability even under high surge conditions. The aluminum oxide layer, which acts as the dielectric, is carefully engineered to maintain its integrity when subjected to high initial current surges. This allows the capacitor to handle the thermal and electrical stress caused by sudden current spikes during power-up without degradation of performance, offering long-term reliability in demanding applications.

High Ripple Current Capacity

The VH Small-Sized Aluminum Electrolytic Capacitor is designed with a high ripple current capacity, meaning it can efficiently manage the power dissipation that occurs when surge conditions are encountered. Ripple current is the AC component superimposed on the DC voltage and is particularly significant in applications where the capacitor is part of the filtering or smoothing circuit. The high ripple current rating ensures that the capacitor can endure high-frequency switching without excessive heating, which might lead to failure. During startup, when high inrush currents are common, the capacitor's ability to handle the instantaneous surge is critical to ensuring its durability and efficient operation. Without the ability to handle ripple current, the electrolyte inside the capacitor could degrade, leading to reduced performance and a shorter lifespan. The VH capacitor mitigates these risks by incorporating robust internal components designed to dissipate heat more effectively during surge events.

Low ESR (Equivalent Series Resistance)

The low ESR (Equivalent Series Resistance) of the VH Small-Sized Aluminum Electrolytic Capacitor plays a crucial role in its ability to manage high inrush currents and surge conditions. ESR refers to the internal resistance that impedes the flow of current, causing power loss and heat generation. Low ESR ensures that the capacitor is highly efficient at transferring power without significant losses, especially when subjected to high-frequency or high-voltage surges. This is particularly important during system startup, when there are often sharp increases in current. High ESR capacitors would generate more heat, which could lead to thermal damage, while the VH capacitor’s low ESR ensures that minimal energy is lost as heat, preventing the risk of damage due to excessive current fluctuations. The low ESR also reduces the voltage drop during surge conditions, making the capacitor ideal for power-sensitive applications such as power supplies or switching regulators.

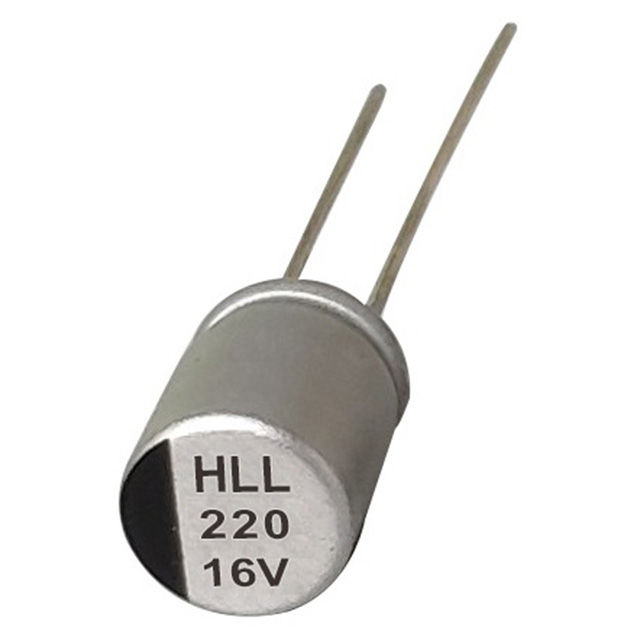

Capacitor Size and Design Optimization

The compact size of the VH Small-Sized Aluminum Electrolytic Capacitor makes it particularly suited for applications where space is at a premium. Despite its small size, it is designed for high capacitance and high-frequency performance, meaning it can handle both high inrush currents and surge conditions without compromising on its electrical performance. The capacitor's design optimizes the surface area of the electrolyte to ensure that it can absorb the surge currents efficiently. In many cases, compact capacitors are used in power supply circuits, where inrush currents are common, such as during DC-to-DC conversions or in motor drives. The efficient use of space allows for a greater amount of electrolyte surface area in a compact package, ensuring that even in constrained environments, the capacitor can handle high surge conditions without exceeding its thermal limits. This makes it a versatile solution for applications that require both high current-handling capability and a small form factor.

Soft-Start and Protective Circuits

To mitigate the damaging effects of high inrush currents, many systems using the VH Small-Sized Aluminum Electrolytic Capacitor incorporate soft-start or pre-charging circuits. These circuits gradually ramp up the voltage applied to the capacitor, rather than exposing it to an immediate surge, which helps protect the capacitor from excessive stress. By implementing these soft-start mechanisms, the current flow into the capacitor is controlled, reducing the risk of over-stress during initial power-up. In some instances, capacitors are equipped with internal inrush current limiting circuits or have built-in surge protection mechanisms that allow them to handle these startup spikes. These features ensure that the capacitor performs optimally during power-up and throughout the operational life of the system, maintaining both the longevity and reliability of the component.