Voltage Rating and Capacitor Breakdown

-

Rated Voltage and Breakdown: Each Surface Mount Capacitor has a specific voltage rating—this is the maximum continuous voltage that the capacitor can safely withstand across its terminals without experiencing damage. The voltage rating is crucial because when the voltage exceeds the rated capacity, the dielectric material (the insulating layer) within the capacitor can break down. This breakdown occurs when the electrical stress (the applied voltage) becomes greater than the material’s ability to resist the flow of electricity, causing a short circuit or complete failure of the capacitor. In high-voltage power circuits, where the voltage levels can fluctuate or spike, choosing capacitors with an appropriate voltage rating is paramount to ensuring they do not fail under extreme conditions.

-

Consequences of Exceeding Voltage Rating: If the voltage applied to the capacitor exceeds the rated limit, the dielectric material will undergo electrical breakdown. This leads to catastrophic failure, including leakage currents, reduced capacitance, and in extreme cases, thermal runaway, which could compromise the safety of the entire circuit. In high-voltage applications, this can result in significant damage to both the capacitor and other components in the circuit.

Derating for Reliability and Longevity

-

What is Derating?: Derating is the practice of operating a component, such as a capacitor, at a lower voltage than its maximum rated value to ensure extended reliability and performance over time. In high-voltage circuits, it is common to choose a Surface Mount Capacitor with a voltage rating that is higher than the actual operating voltage of the circuit. The general rule of thumb for derating is using a capacitor rated for 50-100% more than the maximum operating voltage, depending on the application. This extra margin ensures that the capacitor can handle voltage surges or spikes without damage.

-

Why Derating Matters in High-Voltage Circuits: High-voltage power circuits often experience transients, such as voltage spikes due to switching events, lightning strikes, or other disruptions in the power supply. These transients can exceed the typical operating voltage by significant margins, which makes derating essential. By selecting a capacitor with a higher voltage rating than the actual operating voltage, manufacturers ensure that the capacitor will function safely and consistently, even during these unpredictable events. Furthermore, derating helps in minimizing wear on the capacitor, ensuring it lasts longer and operates with fewer chances of failure under stressful conditions.

Impedance and Current Handling at High Voltage

-

Impedance in High-Voltage Circuits: The voltage rating of a Surface Mount Capacitor also affects its impedance characteristics. Impedance refers to the total opposition a capacitor offers to the flow of alternating current (AC), and it is a key factor in its ability to filter signals, smooth power supplies, and handle high-frequency signals. In high-voltage circuits, impedance becomes a critical parameter because the capacitor’s impedance can vary significantly with voltage. A higher voltage-rated capacitor will often have a lower internal resistance (also referred to as ESR - Equivalent Series Resistance), which means it can handle higher currents more efficiently without significant heating or energy loss.

-

Current Handling: In high-voltage applications, capacitors are often subjected to high currents, particularly in power supply circuits or DC-link capacitors used in inverters and other power electronics. A higher voltage rating typically correlates with a capacitor’s ability to handle higher current levels without excessive heating. This is because the materials and construction techniques used to build capacitors rated for high voltage are designed to handle higher electrical stress, thereby improving their ability to safely dissipate heat and maintain performance under load.

Capacitor Type and Voltage Ratings

-

Ceramic Capacitors: Among the different types of Surface Mount Capacitors, ceramic capacitors are particularly well-suited for high-voltage applications due to their high voltage ratings and the materials used for their dielectric layer. Ceramic capacitors typically have voltage ratings ranging from a few volts up to several kilovolts, making them ideal for high-voltage power circuits. However, the capacitance value and temperature stability of ceramic capacitors can be impacted by their voltage rating. For example, Class II and Class III ceramic capacitors, which are often used in high-voltage power supplies, may experience a reduction in capacitance when exposed to high voltages. This behavior is known as the voltage coefficient of capacitance (VCC).

-

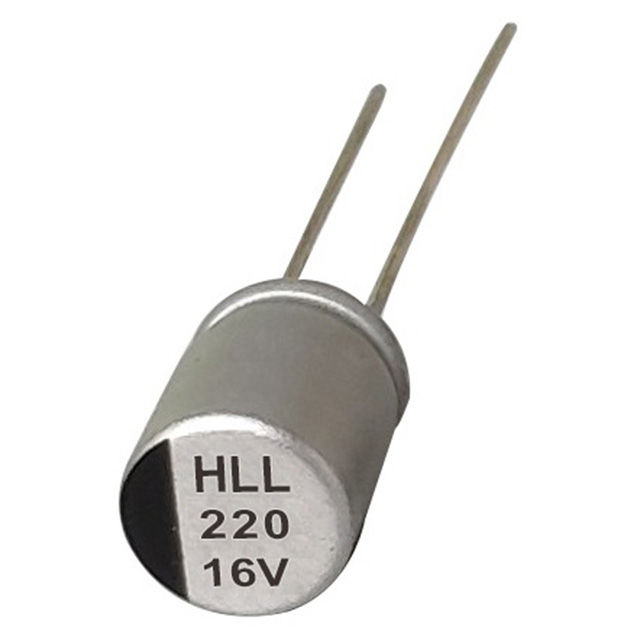

Tantalum and Aluminum Capacitors: Tantalum and aluminum electrolytic capacitors generally have lower voltage ratings than ceramic capacitors and are more commonly used in lower voltage applications (typically below 50V). While they offer high capacitance values, they are not ideal for circuits with high voltage demands because they can have poorer performance at higher voltages due to dielectric breakdown. These types of capacitors are often used for filtering and smoothing tasks in DC power supply circuits but may not be reliable for high-voltage, high-power applications.