Introduction to Aluminum Capacitors: What You Need to Know

Aluminum capacitors, specifically aluminum electrolytic capacitors, are crucial components in modern electronics, playing a significant role in power regulation, filtering, and energy storage. Their unique design and characteristics make them indispensable in a wide range of electronic applications, from consumer electronics to industrial machinery. Understanding how aluminum capacitors work, their features, and the reasons for their widespread use is key to comprehending their importance in electronic devices.

1. The Basics of Capacitors

Capacitors are passive electronic components that store electrical energy temporarily and release it when needed. They consist of two conductive plates separated by a dielectric material, which could be a vacuum, air, or a solid, liquid, or gel material. The primary function of a capacitor is to store charge and regulate voltage levels in circuits. When an electrical current is applied, the capacitor charges, and it discharges when the current ceases. Capacitors are used in various applications, including smoothing power supplies, tuning circuits, and filtering noise.

The aluminum electrolytic capacitor is a type of electrolytic capacitor, where the dielectric is formed from an oxide layer on the surface of an aluminum foil. This unique construction enables aluminum capacitors to have high capacitance values, making them suitable for applications requiring large energy storage.

2. What Makes Aluminum Capacitors Unique?

The construction of aluminum electrolytic capacitors differs from other capacitor types in several ways. The key feature is their high capacitance value compared to other capacitor types like ceramic or tantalum capacitors. This is due to the use of a thin oxide layer as the dielectric, which allows for a larger surface area within the same physical size.

The basic structure of an aluminum capacitor consists of an anode made from a rolled sheet of aluminum foil, a cathode typically made of a conductive liquid or solid electrolyte, and a separator to prevent electrical short circuits. The anode is coated with a thin layer of aluminum oxide, which forms the dielectric. The capacitance of the capacitor is directly related to the surface area of the aluminum foil and the thickness of the oxide layer, which is why aluminum electrolytic capacitors are often used in applications where high capacitance is required.

3. How Aluminum Capacitors Function

In simple terms, the functioning of aluminum capacitors involves storing and releasing electrical energy. When a voltage is applied across the anode and cathode, the capacitor stores energy in the form of an electric field within the oxide layer. The energy is discharged when the capacitor is part of a circuit and the voltage changes. The electrolyte plays a crucial role in ensuring a conductive path between the cathode and the aluminum foil.

The behavior of aluminum capacitors is often characterized by their high capacitance-to-volume ratio, which allows them to store a large amount of energy in a small package. This is why they are often used in power supply filtering to smooth out the voltage fluctuations in DC power supplies. The voltage rating of aluminum capacitors is also a key consideration, as they are designed to handle voltages typically in the range of 6V to 600V.

4. The Electrolyte and Its Role

The electrolyte in aluminum capacitors is a conductive material that facilitates the flow of charge between the anode and cathode. In traditional aluminum electrolytic capacitors, the electrolyte is usually a liquid or gel, which plays a vital role in determining the capacitor's performance, particularly its leakage current and overall efficiency. The liquid electrolyte is absorbed by the paper separator or wound foil structure, making it an essential part of the capacitor's functionality.

The electrolyte's conductivity and chemical stability are critical to the longevity and reliability of the capacitor. In fact, the performance of aluminum capacitors often depends heavily on the quality and composition of the electrolyte used. The resistance of the electrolyte determines the leakage current, which is the small amount of current that flows through the capacitor even when it is not in use.

5. Types of Aluminum Electrolytic Capacitors

Aluminum capacitors come in a variety of configurations, each designed for different purposes. The most common types are:

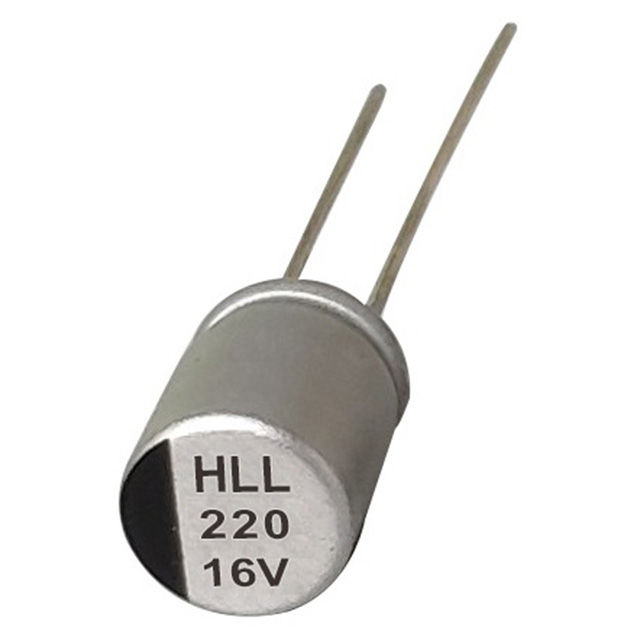

-

Radial Aluminum Capacitors: These capacitors have leads extending radially from the bottom of the cylindrical casing. Radial capacitors are often used in general-purpose applications where the capacitor needs to be mounted on a PCB (printed circuit board) in a compact space.

-

Axial Aluminum Capacitors: These capacitors have leads extending from each end of the cylindrical body, allowing them to be mounted in a straight line along the PCB. They are commonly used in older electronic devices or applications where space constraints are not as critical.

-

SMD Aluminum Capacitors: Surface-Mount Devices (SMD) aluminum capacitors are designed for automated assembly in modern electronics. These capacitors are small and flat, allowing them to be mounted directly on the surface of a PCB without the need for holes.

Each of these types serves specific needs in the electronics manufacturing industry, with radial capacitors typically used for higher-capacitance applications and SMD capacitors for compact devices.

6. Capacitance and Voltage Ratings

The key characteristics of aluminum capacitors that influence their performance are capacitance and voltage rating. Capacitance is measured in farads (F), but most aluminum capacitors fall in the range of microfarads (µF) to millifarads (mF). The capacitance value determines how much charge the capacitor can store. Higher capacitance allows for more energy storage, making these capacitors ideal for power-supply filtering and energy storage applications.

The voltage rating of an aluminum capacitor specifies the maximum voltage the capacitor can safely withstand without risk of failure. Exceeding this rating can cause the capacitor to break down, leading to leakage or even catastrophic failure in some cases. The voltage range of aluminum capacitors typically spans from 6V to several hundred volts, depending on the application.

7. Applications of Aluminum Capacitors

Aluminum electrolytic capacitors are widely used across various industries and applications. Some of the most common uses include:

-

Power Supply Filters: In power supplies, aluminum capacitors help smooth the DC voltage by filtering out ripples and fluctuations. Their high capacitance values make them ideal for this task.

-

Audio Equipment: Aluminum capacitors are used in audio systems, especially in amplifiers and equalizers, where they help to filter out unwanted noise and smooth the output signal.

-

Industrial Equipment: In industrial machinery, aluminum capacitors are used for energy storage and to help regulate voltage in electrical circuits. Their reliability in high-temperature environments makes them suitable for industrial applications.

-

Consumer Electronics: Aluminum capacitors are found in various consumer electronics such as televisions, radios, laptops, and smartphones due to their compact size and high capacitance.

8. Advantages of Aluminum Capacitors

Aluminum capacitors are preferred in many applications due to their cost-effectiveness and high capacitance values. Compared to other capacitor types like tantalum or ceramic capacitors, aluminum capacitors are typically less expensive and offer a better capacitance-to-volume ratio. Their ability to handle high-voltage applications while remaining compact and cost-efficient makes them an attractive choice in both commercial and industrial sectors.

Additionally, aluminum capacitors can operate effectively in a wide range of environmental conditions. They can withstand high temperatures, making them suitable for use in harsh environments like power supplies for industrial machinery and automotive systems.

9. Limitations of Aluminum Capacitors

While aluminum capacitors are widely used, they are not without limitations. One of the most significant drawbacks is their relatively short lifespan compared to other types of capacitors. The electrolyte inside aluminum capacitors can dry out over time, especially in high-temperature environments, which can cause a decrease in capacitance and an increase in leakage current. This is why proper storage and handling are essential for ensuring the longevity of aluminum capacitors.

Another limitation is their voltage tolerance. Although aluminum capacitors can handle high voltage, they have a relatively narrow operating range. Exceeding the rated voltage can lead to catastrophic failure, so it is essential to select capacitors with appropriate ratings for each application.

Key Features of Aluminum Capacitors: High Capacitance and Durability

Aluminum capacitors, specifically aluminum electrolytic capacitors, are indispensable components in the world of electronics. Known for their high capacitance and durability, they are used in a wide range of applications that require reliable energy storage, filtering, and voltage regulation. Understanding the key features of aluminum capacitors, especially their capacitance and durability, is critical in determining their role and optimal use in various electronic systems. This section delves into the technical details and characteristics that make aluminum capacitors highly valued in the electronics industry.

1. High Capacitance: The Core Advantage

One of the defining characteristics of aluminum electrolytic capacitors is their high capacitance, which enables them to store substantial amounts of energy. Capacitance is a measure of a capacitor's ability to store electrical charge, and in the case of aluminum capacitors, this ability is significantly enhanced by the unique design and materials used in their construction.

The oxide layer formed on the aluminum foil serves as the dielectric material, and its thinness allows for a larger surface area for charge storage compared to other types of capacitors like ceramic capacitors. This high surface area is what allows aluminum capacitors to achieve high capacitance values, often ranging from 1 µF to several thousand µF.

This feature makes aluminum electrolytic capacitors ideal for applications requiring significant energy storage in a small, compact form. Power supply circuits, for example, rely on the high capacitance of aluminum capacitors to smooth out voltage fluctuations and provide a stable output, ensuring that electrical devices receive the required steady power supply.

Aluminum capacitors can also achieve high capacitance-to-volume ratios, which means they can provide large amounts of energy storage while maintaining a relatively small physical size. This is essential in applications like consumer electronics and automotive systems, where space is often limited but high energy storage is necessary.

2. Voltage Rating and its Impact on High Capacitance

The voltage rating of an aluminum capacitor is directly related to its capacitance. The voltage rating specifies the maximum voltage the capacitor can safely handle before it risks damage. Typically, aluminum electrolytic capacitors are available in a wide range of voltage ratings, from 6V up to 600V and beyond, depending on the requirements of the application.

When selecting an aluminum capacitor for a specific application, it is crucial to match the voltage rating with the operating conditions of the circuit. The higher the voltage rating, the thicker the oxide layer must be to prevent breakdown, which can affect the overall capacitance. As the voltage rating increases, the physical size of the capacitor may also increase due to the thicker dielectric required.

The relationship between voltage rating and capacitance in aluminum capacitors highlights the trade-offs designers must consider. Higher capacitance typically requires a larger capacitor, but advancements in materials and design techniques have led to capacitors with improved capacitance density, providing high capacitance in a compact size while still maintaining a high voltage rating.

3. Durability and Long Lifespan of Aluminum Capacitors

Durability is another essential feature that makes aluminum electrolytic capacitors so widely used in electronics. These capacitors are designed to withstand a variety of environmental conditions, including temperature extremes and electrical stress, making them suitable for both consumer and industrial applications.

The electrolyte plays a key role in the durability of aluminum capacitors. In traditional aluminum capacitors, the electrolyte is typically a liquid or gel, which helps to form a conductive path between the anode and cathode. The electrolyte’s quality and chemical stability are crucial for the capacitor’s long-term performance. High-quality electrolytes are designed to maintain their properties even after years of use, ensuring that the capacitor remains functional over extended periods.

In terms of temperature tolerance, aluminum capacitors are able to operate in a wide range of temperatures, often from -40°C to +85°C, with some specialized versions even designed to withstand temperatures as high as +125°C. The ability to operate in harsh environmental conditions, including extreme heat and cold, makes aluminum capacitors a preferred choice for applications such as automotive systems, industrial equipment, and power electronics.

4. Life Expectancy and Factors Affecting Durability

The lifetime of an aluminum capacitor is primarily determined by the stability of its electrolyte and the thickness of the oxide layer. As the capacitor operates over time, the electrolyte may degrade, especially under high temperatures or when subjected to voltage stress. This degradation can lead to a loss of capacitance and an increase in leakage current, which can ultimately cause the capacitor to fail.

One key factor affecting the durability of aluminum capacitors is operating temperature. High temperatures accelerate the drying out of the electrolyte, which reduces the capacitance and increases the risk of failure. This is why aluminum capacitors used in high-temperature applications are often designed with specialized high-temperature electrolytes to extend their lifespan.

To improve lifespan and durability, some aluminum capacitors are equipped with venting mechanisms to release pressure that may build up due to internal gas formation, preventing catastrophic failure. Sealed designs help protect the capacitor from external contaminants, which can also contribute to degradation.

Another factor affecting durability is the electrical stress experienced by the capacitor. High ripple currents and frequent voltage surges can cause internal heating, which can hasten the breakdown of the electrolyte and oxide layer. Therefore, it is essential to select capacitors that are rated for the specific ripple current and voltage conditions of the application.

5. Leakage Current and Its Impact on Durability

Leakage current is the small amount of current that flows through the capacitor even when it is not in use. While aluminum capacitors are designed to minimize leakage current, it is still an inherent characteristic of all capacitors. Over time, as the capacitor ages, the leakage current tends to increase, primarily due to the degradation of the oxide layer and electrolyte.

The rate of increase in leakage current can significantly affect the performance and durability of the capacitor. High leakage current can result in reduced efficiency in circuits that rely on precise voltage regulation and energy storage. For example, in power supply filters, excessive leakage current can undermine the capacitor’s ability to smooth voltage, leading to fluctuations that can damage sensitive components.

To address this, modern aluminum capacitors are designed to minimize leakage current by improving the quality of the oxide layer and electrolyte composition. Capacitors with low leakage current are particularly valuable in applications where long-term reliability is critical, such as in medical devices or aerospace equipment.

6. Improved Designs for Enhanced Durability

Recent advancements in the design and manufacturing of aluminum capacitors have led to improvements in both capacitance and durability. For instance, the introduction of solid aluminum capacitors, which use a solid electrolyte instead of a liquid one, has helped to increase the reliability and life expectancy of these capacitors. Solid electrolytes offer better performance under extreme conditions, such as high temperatures and high voltage.

Furthermore, some hybrid designs combine the benefits of both electrolytic and solid-state capacitors, providing enhanced durability and better performance in high-stress environments. These innovations have opened up new possibilities for aluminum capacitors in applications that demand both high capacitance and long-lasting performance.

7. The Role of Aluminum Capacitors in Modern Electronics

The high capacitance and durability of aluminum electrolytic capacitors make them indispensable in many modern electronic systems. They are widely used in power supply circuits, where they help smooth out voltage fluctuations and provide energy storage for devices that require stable power input. In audio equipment, aluminum capacitors help filter out unwanted noise and smooth the audio signal for better sound quality.

In automotive applications, aluminum capacitors are used to regulate power in systems such as lighting, engine control units (ECUs), and infotainment systems. The durability of these capacitors is particularly important in automotive environments, where temperatures can vary dramatically and reliability is essential for vehicle safety and performance.

In industrial electronics, aluminum capacitors help ensure the stable operation of heavy-duty equipment, such as motors, switchgear, and energy storage systems. Their ability to withstand high current and voltage surges makes them a preferred choice for these demanding applications.

Aluminum Capacitors vs. Other Capacitor Types: A Comprehensive Comparison

Capacitors are essential components in nearly every electronic device. They store and release electrical energy, help smooth out voltage fluctuations, and perform various filtering and tuning tasks in circuits. However, not all capacitors are created equal. Among the many different types, aluminum capacitors stand out due to their unique properties and widespread use. This comparison will explore how aluminum capacitors measure up against other common types, such as ceramic capacitors, tantalum capacitors, film capacitors, and electrolytic capacitors. By understanding the key differences, advantages, and limitations of each, engineers and designers can make more informed decisions when selecting capacitors for specific applications.

1. Aluminum Capacitors: Overview

Aluminum electrolytic capacitors, also known as aluminum capacitors, are a type of electrolytic capacitor that use aluminum as the anode material and a thin layer of aluminum oxide as the dielectric. These capacitors are known for their high capacitance and are typically used in applications requiring large energy storage in a compact form. The main features that distinguish aluminum capacitors include their relatively low cost, high capacitance-to-volume ratio, and ability to handle high voltages.

Aluminum capacitors are available in different configurations, such as radial, axial, and surface-mount, making them versatile for various applications. Their primary applications include power supply filtering, smoothing voltage fluctuations, and energy storage in devices ranging from consumer electronics to industrial equipment.

2. Ceramic Capacitors: Key Characteristics

Ceramic capacitors are one of the most widely used types of capacitors. They use a ceramic material as the dielectric and offer high stability, small size, and high-frequency performance. Ceramic capacitors are divided into Class I, Class II, and Class III types based on their dielectric properties, with Class I capacitors offering the best temperature stability.

-

Size and Capacitance: Ceramic capacitors are typically much smaller than aluminum capacitors, making them ideal for compact applications. However, their capacitance tends to be lower than that of aluminum capacitors, usually ranging from a few picofarads (pF) to several microfarads (µF).

-

Voltage Rating: Ceramic capacitors have a wide voltage range, typically up to several hundred volts. However, high-voltage ceramic capacitors are generally larger than those with lower voltage ratings.

-

Applications: Ceramic capacitors are commonly used in high-frequency circuits, filtering, and timing applications due to their low ESR (Equivalent Series Resistance) and stable performance at high frequencies.

Comparison with Aluminum Capacitors:

-

Capacitance: Ceramic capacitors are typically not as suitable for applications requiring high capacitance (like power supply filtering), as their capacitance is much lower than that of aluminum capacitors. Aluminum capacitors have a much higher capacitance-to-volume ratio, making them more suitable for energy storage in low-frequency applications.

-

Temperature Stability: Ceramic capacitors, especially those of Class I type, tend to offer better temperature stability compared to aluminum capacitors, which can degrade over time, especially at high temperatures.

-

Size and Form Factor: Ceramic capacitors are much smaller and lighter than aluminum capacitors, which makes them ideal for compact, miniaturized devices.

3. Tantalum Capacitors: Key Characteristics

Tantalum capacitors are another type of electrolytic capacitor that use tantalum metal for the anode and tantalum oxide as the dielectric. Known for their compact size, high capacitance, and reliability, tantalum capacitors are commonly used in applications where space is constrained but high reliability is required.

-

Capacitance and Voltage: Tantalum capacitors typically have a capacitance range similar to aluminum capacitors but tend to perform better at higher frequencies. They are available in low to medium voltage ratings, generally from 6V to 50V.

-

Durability and Lifespan: Tantalum capacitors are generally more reliable than aluminum capacitors, especially in environments where the capacitor is subjected to frequent or high voltages. They are also less prone to leakage current compared to aluminum electrolytic capacitors.

-

Applications: Tantalum capacitors are often used in military, aerospace, and medical applications, where reliability is critical.

Comparison with Aluminum Capacitors:

-

Capacitance: Tantalum capacitors have a similar capacitance range to aluminum capacitors but typically occupy smaller physical spaces for equivalent capacitance. However, tantalum capacitors are less suited for high capacitance values (above a few thousand microfarads) compared to aluminum capacitors.

-

Cost: Tantalum capacitors tend to be more expensive than aluminum capacitors, especially at higher capacitance values, making them less cost-effective for applications that do not require the reliability and compactness of tantalum capacitors.

-

Reliability: Tantalum capacitors are generally more reliable and have a longer lifespan than aluminum capacitors, making them a better choice for applications where long-term performance is crucial, and failure risks need to be minimized.

4. Film Capacitors: Key Characteristics

Film capacitors are capacitors that use a plastic film (such as polyester, polypropylene, or polystyrene) as the dielectric material. Film capacitors are known for their stable performance, low ESR, and high voltage tolerance, making them ideal for high-precision applications.

-

Capacitance and Voltage: Film capacitors generally have lower capacitance compared to aluminum electrolytic capacitors, typically ranging from a few nanofarads (nF) to a few microfarads (µF). However, they offer high voltage ratings, often exceeding 1,000V.

-

Temperature Stability: Film capacitors offer excellent temperature stability and have lower leakage currents than electrolytic capacitors, making them suitable for precision circuits.

-

Applications: Film capacitors are commonly used in high-frequency applications, audio circuits, timing applications, and in power electronics where high voltage and stability are required.

Comparison with Aluminum Capacitors:

-

Capacitance: Film capacitors have much lower capacitance than aluminum capacitors, which makes them unsuitable for energy storage in high-capacitance applications like power supply filters. Aluminum capacitors, with their higher capacitance, are much better suited for these tasks.

-

Voltage and Stability: Film capacitors are ideal for applications that require high-voltage tolerance and stable performance over time, such as in high-precision circuits. On the other hand, aluminum capacitors offer high capacitance but may suffer from degradation over time, particularly in high-temperature environments.

-

Size: Film capacitors are generally larger and bulkier compared to aluminum capacitors, especially for applications requiring high capacitance. Aluminum capacitors offer a higher capacitance-to-volume ratio, which makes them more efficient in terms of space utilization.

5. Supercapacitors: Key Characteristics

Supercapacitors, also known as ultracapacitors, are a type of capacitor designed to store a large amount of energy. Unlike traditional capacitors, supercapacitors store energy electrostatically, rather than chemically. They offer extremely high capacitance values, typically ranging from 1,000 µF to several farads (F), which makes them suitable for applications requiring large energy storage and rapid charge/discharge cycles.

-

Capacitance and Energy Storage: Supercapacitors have a much higher capacitance than standard aluminum capacitors, making them ideal for energy storage in applications like electric vehicles, solar power systems, and backup power solutions.

-

Voltage and Efficiency: While supercapacitors have lower voltage ratings than traditional capacitors (typically around 2.7V to 5V per cell), they excel at delivering rapid bursts of energy with minimal loss, making them suitable for applications where quick discharge is needed.

-

Applications: Supercapacitors are used in energy storage systems, backup power, regenerative braking systems, and power grid stabilization.

Comparison with Aluminum Capacitors:

-

Capacitance: Supercapacitors offer a much higher capacitance than aluminum capacitors, making them suitable for large-scale energy storage and power supply systems. Aluminum capacitors, however, are better suited for applications that require energy filtering and voltage regulation.

-

Energy Density: While aluminum capacitors have high capacitance, they are less efficient at storing large amounts of energy compared to supercapacitors, which are designed specifically for high-energy storage.

-

Cost and Application Suitability: Supercapacitors are more expensive and generally used in specialized applications like electric vehicles or grid energy storage. In contrast, aluminum capacitors are more affordable and are typically used in more common electronic circuits.

Applications of Aluminum Capacitors in Power Supply Circuits

Aluminum capacitors, specifically aluminum electrolytic capacitors, play a pivotal role in the functioning of modern power supply circuits. Their unique characteristics, such as high capacitance, compact size, and cost-effectiveness, make them essential components in a wide range of applications, particularly where high energy storage and voltage stabilization are critical. Power supply circuits, whether used in consumer electronics, industrial machinery, or automotive systems, rely on these capacitors for a variety of tasks. This section will explore the specific applications of aluminum capacitors in power supply circuits, detailing their functions, advantages, and the reasons why they are indispensable in these systems.

1. Power Supply Filtering: Smoothing Voltage Fluctuations

One of the primary applications of aluminum electrolytic capacitors in power supply circuits is in voltage filtering, particularly in DC power supplies. In most power supply systems, an AC voltage is converted to DC voltage using components like rectifiers. However, the DC voltage produced by rectifiers is not smooth and often contains ripple voltage or fluctuations caused by the pulsating nature of the AC input. To ensure that the output voltage remains stable and suitable for powering electronic devices, a capacitor is needed to smooth these fluctuations.

Aluminum capacitors are ideal for this task due to their high capacitance values. By storing energy during the peaks of the input voltage and releasing it during the troughs, aluminum electrolytic capacitors effectively filter out the ripple. The larger the capacitance of the capacitor, the better it can smooth the output voltage. High capacitance capacitors, such as those rated in the thousands of microfarads (µF), are commonly used to store significant amounts of energy and discharge it when the voltage dips. The low ESR (Equivalent Series Resistance) of aluminum capacitors allows them to charge and discharge quickly, providing effective filtering without causing significant voltage loss.

These capacitors are often placed in the output stage of power supplies, where they work to smooth out the rectified DC voltage before it is delivered to the electronic load. Ripple reduction is especially critical in sensitive devices such as audio equipment, medical devices, and high-frequency circuits, where fluctuations in voltage can lead to noise or malfunction.

2. Energy Storage and Buffering

Another critical application of aluminum capacitors in power supply circuits is their use in energy storage and buffering. In DC-DC converters and AC-DC power supplies, aluminum electrolytic capacitors act as energy storage devices that help provide a stable power supply. These capacitors can store energy during periods of high voltage and discharge it when the voltage drops, ensuring a consistent power output to the connected load.

The ability of aluminum capacitors to store a large amount of energy in a relatively small form factor makes them perfect for energy buffering in applications where the load may experience sudden changes in power demand. For instance, in switch-mode power supplies (SMPS), the capacitor can store energy during the on phase of the switching cycle and release it during the off phase, providing a continuous flow of energy to the load.

In battery-backed systems, aluminum electrolytic capacitors can help smooth out the power delivered by the battery, ensuring a steady voltage output as the battery discharges. They also play a crucial role in power supply systems for renewable energy applications, such as solar power or wind energy, where the incoming power may be intermittent or unstable. In these cases, capacitors help smooth the power and ensure that the system operates efficiently without fluctuations.

3. Power Factor Correction (PFC)

Power factor correction (PFC) is a technique used in power supply systems to improve the efficiency of power transmission. In systems that use AC to DC conversion, the current waveform often becomes distorted, leading to a low power factor. A low power factor indicates that the system is not using electrical power as efficiently as possible, resulting in wasted energy and higher operational costs. Aluminum capacitors play a significant role in power factor correction by helping to reduce the reactive power and improving the overall efficiency of the power supply.

In PFC circuits, aluminum capacitors are used in conjunction with inductors to form a LC filter that can adjust the phase difference between the voltage and current waveforms. By storing and releasing energy, these capacitors reduce the harmonic distortion caused by the AC input, making the power supply system more efficient and ensuring that more of the electrical energy is delivered to the load. High-capacitance aluminum capacitors are particularly effective in PFC circuits, where their large energy storage capacity helps to minimize voltage drops and improve the overall power quality.

PFC is essential in applications such as industrial equipment, consumer electronics, and data centers, where maintaining an optimal power factor is critical for reducing energy consumption and lowering costs. In such systems, aluminum electrolytic capacitors provide a cost-effective and reliable means of correcting the power factor and improving the efficiency of the power supply.

4. Start-Up Capacitors in Motor Drive Circuits

In motor drive circuits, especially in applications like electric vehicles (EVs), industrial motors, and air conditioning systems, aluminum electrolytic capacitors are used to facilitate the start-up process. Induction motors and other AC motors require a high current to start, which can place a significant strain on the power supply. Aluminum capacitors help to smooth the current surge during the start-up phase, ensuring that the motor starts without causing voltage dips or damaging the power supply.

These capacitors store a significant amount of energy and discharge it rapidly when the motor is turned on. The high capacitance of aluminum electrolytic capacitors allows them to provide the necessary power during motor start-up while reducing the strain on the power supply. Once the motor reaches a steady operational speed, the capacitor's role in the circuit diminishes, and the power supply takes over.

In variable frequency drives (VFDs) and inverter systems, aluminum capacitors help maintain a stable voltage during start-up and ensure that the system runs efficiently, reducing wear and tear on components and minimizing energy consumption.

5. Surge Protection and Voltage Regulation

Surge protection and voltage regulation are crucial aspects of power supply circuits, especially in environments where the power input can experience spikes or surges, such as in industrial plants, automated systems, and telecommunication networks. Aluminum electrolytic capacitors are used in surge protection circuits to help absorb and dissipate excess voltage, preventing damage to sensitive components.

When a voltage spike occurs, the aluminum capacitor can quickly absorb the excess energy and store it, preventing the surge from reaching the load. The large capacitance of aluminum electrolytic capacitors makes them particularly effective at handling voltage spikes in systems with high power requirements. Once the surge has passed, the capacitor discharges the energy and restores the circuit to normal operation.

In addition to surge protection, aluminum capacitors play a key role in voltage regulation. In power supplies that require stable voltage output across varying loads, aluminum capacitors help maintain the voltage level by smoothing fluctuations and ensuring that the voltage delivered to the load remains consistent. This is particularly important in sensitive devices such as microcontrollers, communication systems, and medical equipment, where even small variations in voltage can lead to malfunction.

6. Power Supply Capacitors in Renewable Energy Systems

In renewable energy systems, such as solar inverters or wind turbine power systems, aluminum capacitors are essential for regulating the power output and stabilizing the voltage delivered to the grid or to the load. These systems often experience fluctuations due to varying energy input, and aluminum electrolytic capacitors help to smooth the power and ensure a stable, continuous supply.

Aluminum capacitors are used in solar power inverters to filter out the ripples in the DC voltage generated by solar panels. These capacitors help convert the DC voltage into a stable AC output that can be fed into the power grid. Similarly, in wind energy systems, aluminum capacitors help to regulate the power output from the wind turbines and ensure that the generated electricity is delivered with minimal fluctuations.

The large energy storage capacity of aluminum capacitors makes them ideal for handling the variable power output from renewable energy sources. In grid-tied systems, they help to stabilize the power output, improving the efficiency of the system and reducing the likelihood of disruptions caused by fluctuations in energy generation.

Why Aluminum Capacitors Are Essential for Audio Equipment

Aluminum capacitors, specifically aluminum electrolytic capacitors, play a vital role in the performance of audio equipment. From amplifiers to sound systems, these capacitors are crucial for ensuring high-quality audio output, stability, and longevity in various audio devices. They are favored in the audio industry due to their high capacitance, affordability, and reliability. This section explores why aluminum capacitors are essential components in audio equipment, focusing on their role in power supply filtering, voltage regulation, audio signal smoothing, and performance enhancement.

1. Power Supply Filtering for Clean Audio Signals

One of the primary roles of aluminum capacitors in audio equipment is in power supply filtering. Audio systems require a clean, stable power supply to ensure high-quality sound reproduction. However, power supplies often introduce voltage fluctuations, noise, and ripples that can interfere with audio signals and degrade sound quality. These fluctuations, also known as ripple voltage, are a byproduct of the rectification process used in power supplies, where alternating current (AC) is converted to direct current (DC).

Aluminum electrolytic capacitors are used to smooth out this ripple by filtering the DC voltage before it reaches the sensitive audio circuitry. The high capacitance of aluminum capacitors makes them ideal for storing energy and releasing it during voltage dips, helping to maintain a stable voltage for the audio equipment. By doing so, they prevent voltage sag and spikes that could otherwise cause unwanted distortion or noise in the audio output.

These capacitors are often placed in the power supply stage of audio equipment, where they act as bulk capacitors. Their large energy storage capability allows them to smooth high-frequency ripples and maintain a consistent voltage, ensuring that the rest of the audio system receives clean power. In high-end audio equipment, such as hi-fi amplifiers and mixing consoles, aluminum capacitors are critical in maintaining the integrity of the audio signal and preventing any audible hum or buzz.

2. Maintaining Stable Voltage in Audio Amplifiers

In audio amplifiers, aluminum capacitors are used to maintain stable voltage levels and provide reliable energy storage. Audio amplifiers, particularly class A and class AB amplifiers, require a constant and stable voltage supply to drive speakers and reproduce sound accurately. Fluctuations in voltage can lead to clipping, distortion, and loss of fidelity, negatively affecting the listening experience.

Aluminum electrolytic capacitors are particularly effective in these applications due to their large capacitance and voltage tolerance. In an audio amplifier, these capacitors store energy during periods of high demand and release it when the load requires additional power, ensuring that the voltage remains steady. This capability is especially important in high-power audio amplifiers, where the demand for current can fluctuate rapidly, particularly during dynamic audio peaks or when driving low-impedance speakers.

Aluminum capacitors help smooth the power rails in the amplifier, reducing the risk of voltage sag or surges that could cause instability or affect the quality of the audio output. They are typically used in filtering capacitors in the power supply or as decoupling capacitors in the signal path to ensure that the amplifier can provide the necessary power to produce clean, undistorted sound.

3. Decoupling and Noise Reduction in Audio Systems

Decoupling is another crucial application of aluminum capacitors in audio equipment. In audio circuits, especially in digital-to-analog converters (DACs), microcontrollers, and pre-amplifiers, electrical noise can interfere with the audio signal and degrade sound quality. This noise often comes from the power supply or other components in the circuit, and it can be introduced through ground loops, high-frequency switching, or crosstalk between components.

Aluminum capacitors are often used as decoupling capacitors to filter out unwanted noise and prevent it from entering the sensitive parts of the audio circuit. When placed near components that are sensitive to noise, these capacitors help to short-circuit high-frequency noise signals and isolate noise sources, ensuring that only the desired audio signal is passed through to the next stage. This application is critical in high-end audiophile equipment where every element of the signal chain is optimized for the highest fidelity.

Decoupling capacitors also help to stabilize the power supply by absorbing any high-frequency transients or voltage spikes that may occur due to switching regulators, inductive loads, or other sources of interference. By reducing these noise sources, aluminum capacitors contribute to clearer, cleaner, and more accurate audio reproduction.

4. Reducing Distortion in Audio Signals

Distortion is one of the most significant factors that can degrade audio quality. In high-fidelity audio equipment, even the slightest distortion can be noticeable, affecting the overall soundstage, clarity, and tonal accuracy. Aluminum capacitors help to minimize distortion in audio systems in several ways.

Firstly, they provide stable power to the audio circuitry, preventing voltage fluctuations that could lead to distortion during the amplification process. When power supply ripple or voltage sag occurs, it can cause the amplifier to distort the audio signal, resulting in harsh, unpleasant sounds. By smoothing the power supply and ensuring that the audio components receive a stable voltage, aluminum capacitors help prevent these issues.

Secondly, aluminum electrolytic capacitors are used in the coupling and bypass stages of audio circuits. In these stages, capacitors help to block DC voltage while allowing AC audio signals to pass through. By blocking unwanted DC components and ensuring that only the clean audio signal is passed to the next stage, aluminum capacitors help to reduce harmonic distortion and maintain the integrity of the original sound source.

5. Enhancing Low-Frequency Response in Subwoofer Systems

In subwoofer systems, aluminum electrolytic capacitors are commonly used to enhance low-frequency response. Subwoofers are designed to reproduce the low-frequency parts of the audio spectrum, which require significant power to produce deep, resonant bass sounds. The high capacitance of aluminum capacitors makes them ideal for storing energy and supplying it rapidly to power the subwoofer’s drivers, ensuring that the subwoofer can produce deep bass without distortion or loss of fidelity.

Aluminum capacitors are used in the low-pass filter stages of subwoofer systems to help filter out higher frequencies and ensure that only the deep bass frequencies are passed to the subwoofer. These capacitors help maintain the clarity and punch of the bass by reducing unwanted high-frequency noise and ensuring that the low frequencies are delivered cleanly to the subwoofer.

Aluminum electrolytic capacitors are used to smooth power delivery to the subwoofer’s amplifier, ensuring a stable voltage and preventing any interruptions in the power supply that could affect the subwoofer’s performance. This is particularly important in systems where the subwoofer is driven by high-powered amplifiers, as the demand for current can fluctuate significantly during dynamic bass moments.