Dielectric Material Selection for High Voltage Tolerance

The dielectric material in Snap-In Capacitor is the core element that determines its ability to withstand transient voltage spikes. High-quality dielectrics, such as polypropylene film, polyester film, or metallized films, exhibit exceptional dielectric strength and high insulation resistance. These materials provide a stable electric field even under sudden voltage surges. The dielectric’s molecular structure allows it to resist breakdown, preventing electrical punctures that could result in short circuits or catastrophic failure. In addition, these dielectrics maintain consistent capacitance across a wide temperature and voltage range, ensuring that the Snap-In Capacitor continues to function reliably even during high-energy transients commonly seen in motor start-up, industrial AC switching, or power factor correction circuits.

Energy Absorption and Ripple Handling Capabilities

Snap-In Capacitors are engineered to absorb transient energy safely without accumulating excessive heat or mechanical stress. During a voltage spike, the capacitor temporarily stores the excess energy, which is then dissipated gradually. Low Equivalent Series Resistance (ESR) design is critical in this process, as it allows the capacitor to handle high ripple currents with minimal heating. Furthermore, metallized film capacitors used in Snap-In designs include self-healing capabilities: if a transient spike causes a tiny puncture in the dielectric, the localized metallization vaporizes, isolating the fault and restoring the insulating property. This mechanism ensures that even repeated spikes do not cause permanent damage, thereby prolonging operational lifespan.

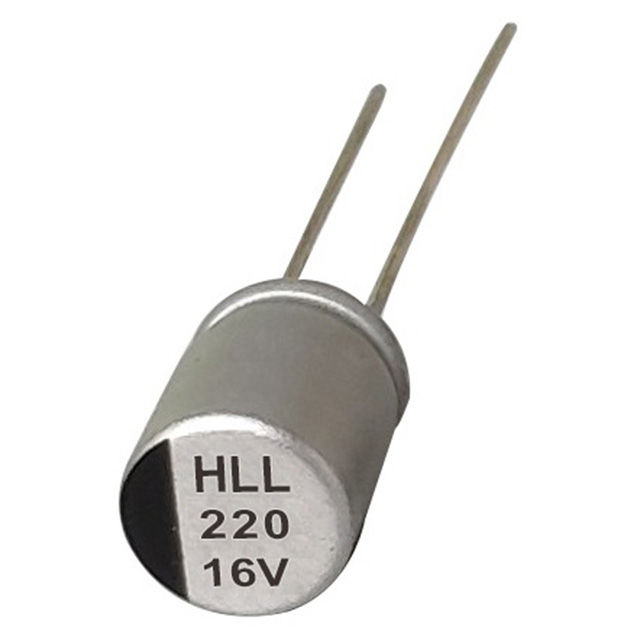

Voltage Margining and Safety Ratings

Manufacturers of Snap-In Capacitors typically specify a working voltage that is significantly lower than the capacitor’s ultimate breakdown voltage. This margin ensures that ordinary line transients, switching surges, or motor start-up currents do not exceed the capacitor’s safe operating limits. By designing the capacitor with a voltage safety margin, engineers ensure that the dielectric experiences minimal electrical stress during transient events. This margining is especially critical in industrial applications where high-voltage spikes occur frequently, such as in power distribution panels, HVAC systems, and motor controllers.

Thermal Management During High-Stress Conditions

Voltage surges generate instantaneous current, leading to localized heating within the capacitor. Snap-In Capacitors are designed to manage this thermal stress effectively through several mechanisms. The low ESR reduces resistive heating, while the dielectric materials themselves are thermally stable, retaining performance at elevated temperatures. Additionally, large surface areas, metallized film layers, and sometimes external heat sinks or encapsulation materials help dissipate heat rapidly. By controlling temperature rise during transient conditions, the capacitor avoids thermal degradation of the dielectric or metallization layers, ensuring consistent electrical performance and longevity.

Encapsulation and Environmental Protection

Snap-In Capacitors are often encapsulated in epoxy or plastic housings, providing a protective barrier against moisture, dust, corrosive gases, and other environmental contaminants. This protection is critical in industrial or outdoor applications where voltage spikes often coincide with harsh environmental conditions. Encapsulation ensures that the dielectric does not absorb moisture, which could reduce insulation resistance or trigger electrical breakdown during transient events. Environmental protection also preserves mechanical integrity, preventing warping or cracking that could compromise the capacitor’s electrical function.

Self-Healing and Surge-Resistant Design Features

Many Snap-In Capacitors employ self-healing metallized film technology. During a transient spike that punctures the dielectric, the surrounding metallized layer vaporizes instantly at the fault site, isolating the defective area and maintaining overall capacitance. This feature allows the capacitor to survive repeated high-energy spikes without significant performance degradation. Surge-resistant designs may also incorporate reinforced metallization, thicker dielectric layers, or optimized electrode geometry, enabling the capacitor to withstand high-energy impulses typical of industrial switching, motor start-up, or lightning-induced transients.

Maintenance of Long-Term Reliability

The combination of high-quality dielectric materials, self-healing metallization, optimized thermal management, voltage margining, and environmental protection ensures that Snap-In Capacitors maintain long-term reliability even under repeated transient conditions. By engineering capacitors to handle high-energy spikes safely, manufacturers minimize capacitance drift, insulation degradation, and mechanical stress over time. When properly specified, installed, and maintained, Snap-In Capacitors provide consistent performance and extended service life, even in demanding industrial, commercial, and motor-driven applications.