The capacitance of the Radial Electrolytic Capacitor is one of the most critical parameters when selecting it for power factor correction. The capacitance value determines how much reactive power the capacitor can supply to the system. Power factor correction involves compensating for the inductive reactance in electrical systems caused by devices such as motors, transformers, and other inductive loads. The required capacitance depends on the amount of reactive power that needs to be corrected to bring the system’s power factor closer to unity (1.0). To determine the appropriate capacitance, one must consider the apparent power (S), the real power (P), and the desired power factor (PF). Capacitors must be chosen to match the power system’s characteristics and correct the power factor efficiently. If the capacitance is too low, the system may still experience poor power factor, resulting in energy losses, whereas excessively high capacitance may lead to overcompensation, causing resonance or oscillations, which can damage equipment.

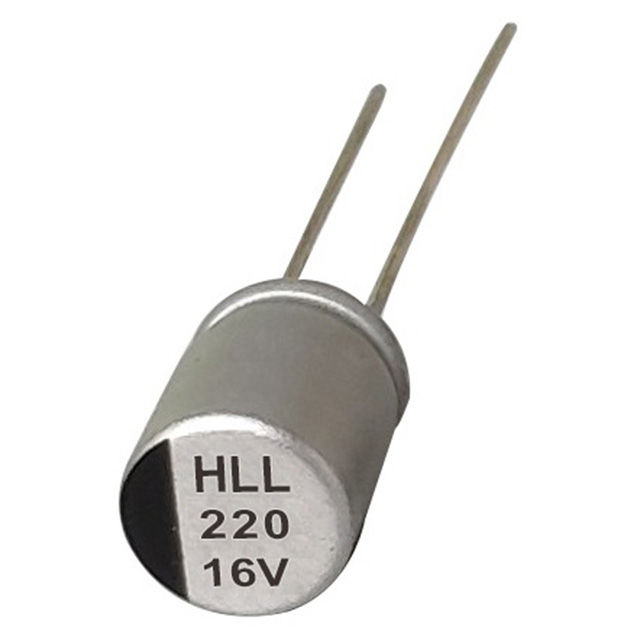

The voltage rating of the Radial Electrolytic Capacitor must exceed the maximum voltage the capacitor will experience in the power factor correction circuit, offering a safety margin. In industrial systems, voltage spikes, surges, and transients can frequently occur, especially in systems with large inductive loads. The capacitor’s voltage rating should generally be at least 1.5 times the maximum system voltage to ensure reliable operation and avoid dielectric breakdown. This precaution helps to prevent capacitor failure due to unforeseen voltage surges, contributing to the stability of the power factor correction system. Choosing capacitors with appropriate voltage ratings ensures that they can handle the operational conditions of industrial environments, where high voltages and transient spikes are common.

The ripple current rating refers to the amount of AC current a capacitor can handle without excessive heating or degradation. In power factor correction applications, ripple currents—generated by the switching of power supplies or due to nonlinear loads—can significantly affect the performance and longevity of the capacitor. Radial Electrolytic Capacitors are typically designed to handle ripple currents, but they must be chosen with a ripple current rating that meets or exceeds the expected current in the circuit. Ripple currents generate heat within the capacitor, and if the capacitor is not rated to handle these currents, it could overheat, leading to premature failure, electrolyte leakage, or even explosion in extreme cases. Users should verify the capacitor's ripple current rating through manufacturer data sheets, ensuring it meets the operational demands of the system.

Industrial systems often operate in harsh environments where temperatures can fluctuate significantly, affecting capacitor performance. The temperature rating of the Radial Electrolytic Capacitor should be chosen based on the maximum expected ambient temperature in the operating environment. Electrolytic capacitors have a maximum operating temperature range of 85°C to 105°C, though some specialized types can handle even higher temperatures. High-temperature capacitors are designed with materials and construction that withstand thermal stresses, while low-temperature rated capacitors might suffer from reduced lifespan and performance degradation at elevated temperatures. Capacitors exposed to excessive heat can suffer from increased internal resistance, reducing efficiency and accelerating failure.